DCS-B bagging scale system grain packing machine

The DCS-B series bagging scale system has an ideal weighing system by adopting advanced microelectronic technologies; it provides perfect control and management of the weighing and packing process.

It's suitable of packing the granule materiel, such as the seed, agricultural product and chemical etc.

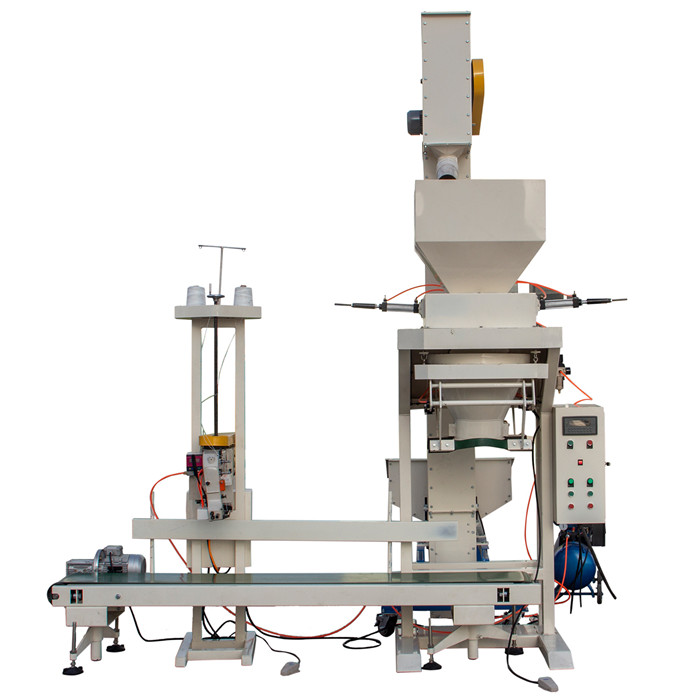

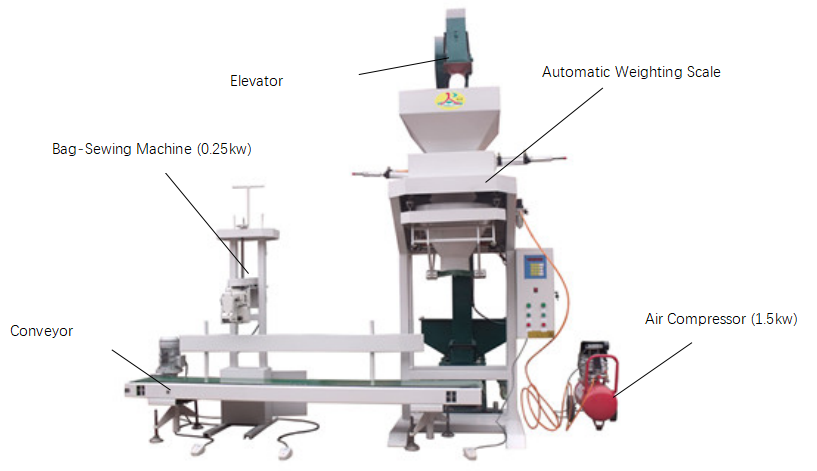

Structure Of Machine

One Semi-automatic bagging scale system includes:

● One Automatic Weighting Scale,

● One Elevator

● One Air Compressor

● One Belt Conveyer

● One Bag-sewing machine (or bag heat-sealing machine)

Technical Data

| Model | DCS-5B | DCS-10B | DCS-25B | DCS-50B |

| Metering Range | 0.5-5 KG | 1-10 KG | 5-25 KG | 10-50 KG |

| Bagging Speed | Over 400 bag/H | Over 360 bag/H | Over 360 bag/H | Over 240 bag/H |

| Accuracy | ±0.2% | |||

| Working Temperature | -10℃ ~ +40℃ | |||

Note: Firstly, you should choose the bagging range, the machine can’t weighting 1-50KG.

For example, if the bagging range is 10-50kg, we will use 100kg weighting sensor; if you weighting 1kg via the 100kg weighting sensor the standard error will be big.

Technical Specification

Accuracy:±0.2%F.S

Metering range: 0.5kg-50kg

Speed(bag/h):120-400/h

Zero shift:<±0.04V/℃

Steelyard shift: <±10ppm/°C

Sampling comparison rate: 50 times/sec

Smallest sub-degrees value: 5

Advantages

High calculating precision, rapid packaging speed, stable function, easy operation.

Adopt advanced techniques on control instrument, sensor, and pneumatic components.

Advanced functions: automatic correction, error alarm, automatic error detection.

All components which have direct contact with bagging materials are made from stainless steel.

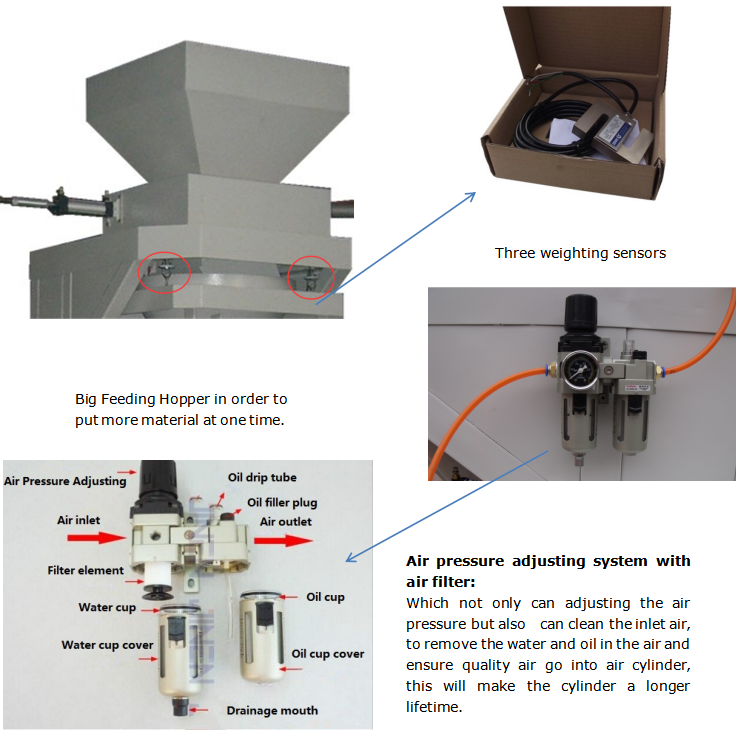

Three weighting sensors

Big Feeding Hopper in order to put more material at one time.

Air pressure adjusting system with air filter:

Which not only can adjusting the air pressure but also can clean the inlet air, to remove the water and oil in the air and ensure quality air go into air cylinder, this will make the cylinder a longer lifetime.

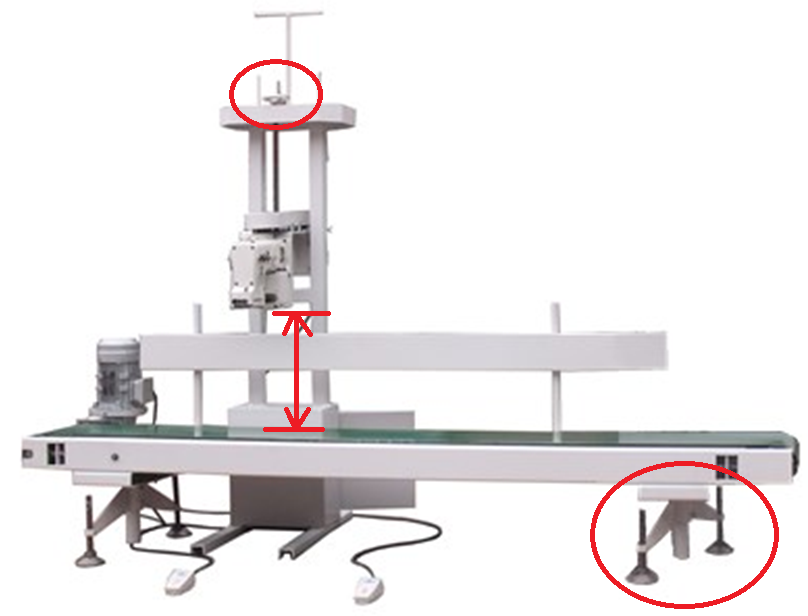

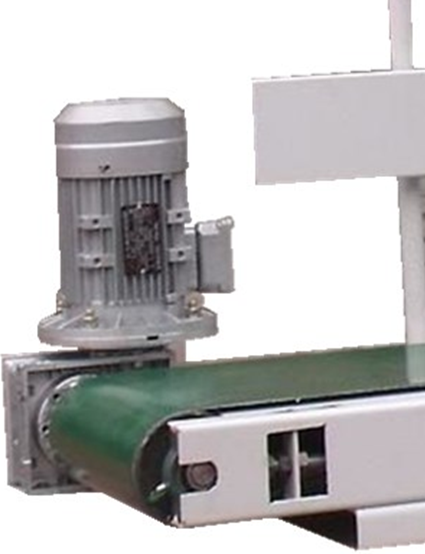

Conveyor belt, it is used for transferring bags.

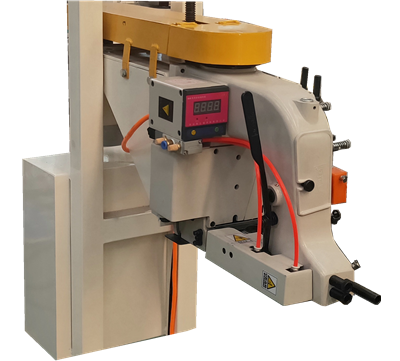

Normal type

By adjusting the height of sewing machine and belt conveyor, it can use different size bags.

Gear motor is belong one part of conveyor belt. It is made from China top brand electricity motor manufacturer, which has high quality and aluminous cover.

Air Compressor

Automatic thread trimming, with counter

Foot Switch

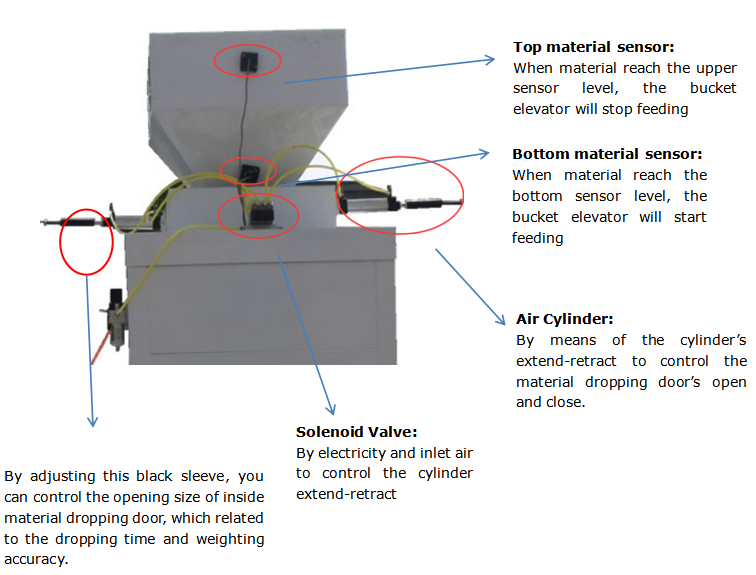

Top material sensor:

When material reach the upper sensor level, the bucket elevator will stop feeding

Bottom material sensor:

When material reach the bottom sensor level, the bucket elevator will start feeding

Air Cylinder:

By means of the cylinder’s extend-retract to control the material dropping door’s open and close.

Solenoid Valve:

By electricity and inlet air to control the cylinder extend-retract

By adjusting this black sleeve, you can control the opening size of inside material dropping door, which related to the dropping time and weighting accuracy.

Accurate Meter Device with finger pressing type screen.

Visualization controller for user. It is easy for adjusting the machine according to different kg for bag