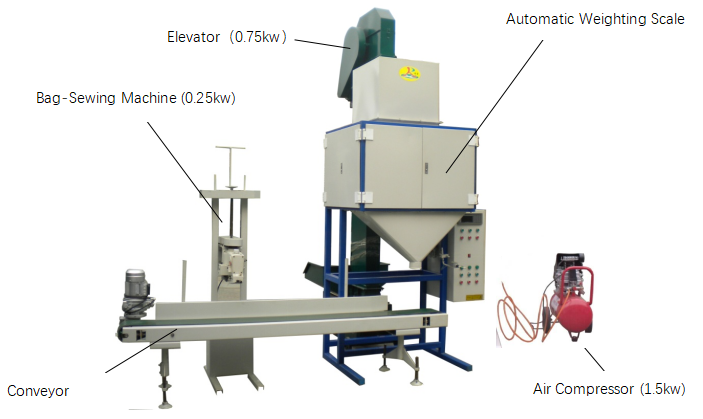

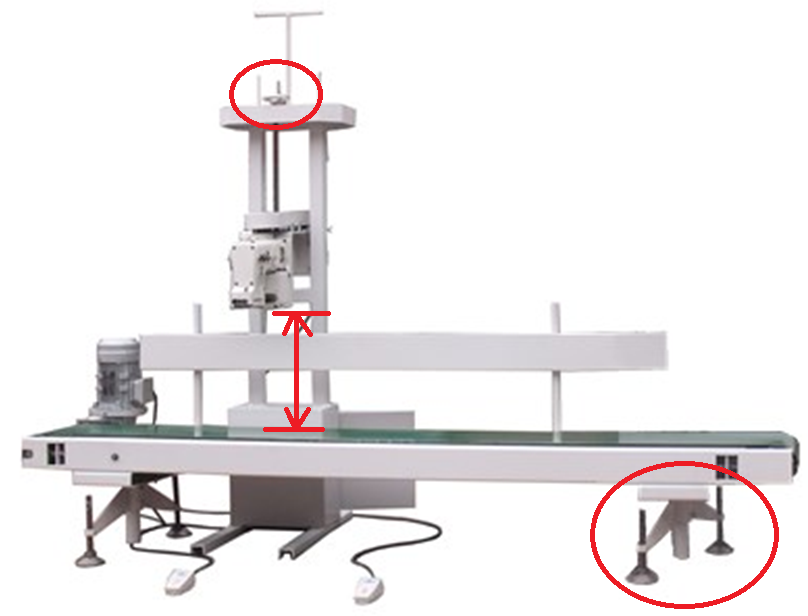

DCS-S bagging scale system grain seed packing bagging machine

Introduction

The DCS-S series bagging scale system has an ideal weighing system by adopting advanced microelectronic technology, which have double weighting scales, the bagging speed is 1.5 times faster than single weighting scale model.

It's suitable of packing the granule materiel, such as the seed, agricultural product and chemical etc.

Structure Of Machine

One Semi-automatic bagging scale system includes:

● One Automatic Weighting Scale,

● One Elevator

● One Air Compressor

● One Belt Conveyer

● One Bag-sewing machine (or bag heat-sealing machine)

Technical Data

| Model DCS-5S DCS-10S DCS-25S DCS-50S |

| Metering Range 0.5-5 KG 1-10 KG 5-25KG 10-50KG |

| Bagging Speed Over 800 bag/H Over 700 bag/H Over 600 bag/H Over 400 bag/H |

| Accuracy ±0.2% |

| Working Temperature -10℃ ~ +40℃ |

Note: Firstly, you should choose the bagging range, the machine can’t weighting 1-50KG.

For example, if the bagging range is 10-50kg, we will use 100kg weighting sensor; if you weighting 1kg via the 100kg weighting sensor the standard error will be big.

Technical Specification

Accuracy:±0.2%F.S

Metering range: 0.5kg-50kg

Speed(bag/h):120-400/h

Zero shift:<±0.04V/℃

Steelyard shift: <±10ppm/°C

Sampling comparison rate: 50 times/sec

Smallest sub-degrees value: 5

Advantages

High calculating precision, rapid packaging speed, stable function, easy operation.

Adopt advanced techniques on control instrument, sensor, and pneumatic components.

Advanced functions: automatic correction, error alarm, automatic error detection.

All components which have direct contact with bagging materials are made from stainless steel.

Top material sensor:

When material reach the upper sensor level, the bucket elevator will stop feeding

Bottom material sensor:

When material reach the bottom sensor level, the bucket elevator will start feeding

There are two sensors in bagging machine bin. Top material sensor and bottom material sensor.

When material reach the weight of your set, the inlet of hopper will be closed and bottom will drop continually until the right weight.

Big Feeding Hopper in order to put more material at one time.

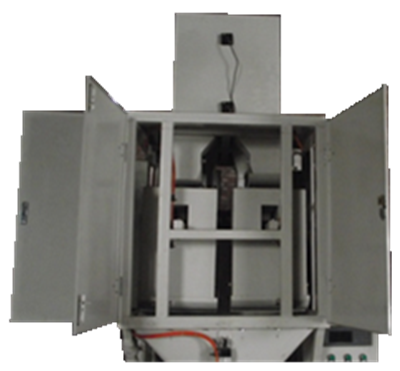

Double weighting scales can increase the packing efficiency.

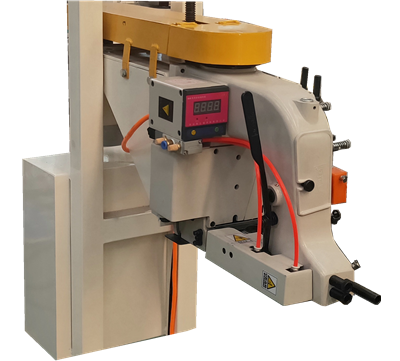

Bags clamping device:

The strong force can fix 50kg bags firmly.

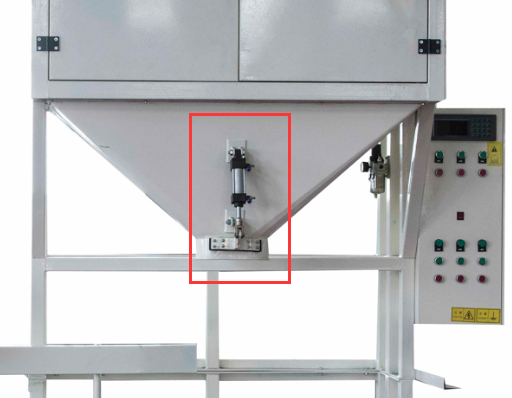

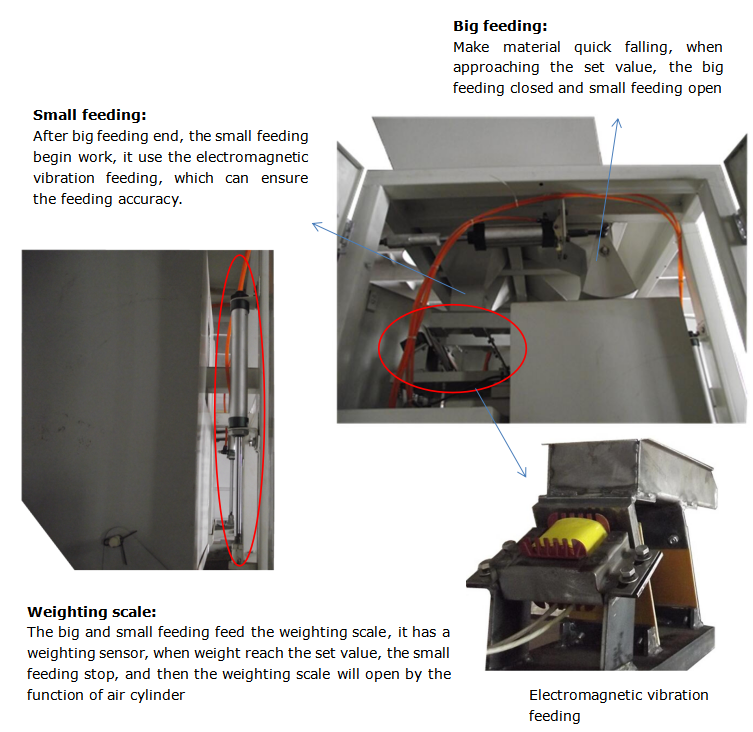

Big feeding:

Make material quick falling, when approaching the set value, the big feeding closed and small feeding open

Small feeding:

After big feeding end, the small feeding begin work, it use the electromagnetic vibration feeding, which can ensure the feeding accuracy.

Weighting scale:

The big and small feeding feed the weighting scale, it has a weighting sensor, when weight reach the set value, the small feeding stop, and then the weighting scale will open by the function of air cylinder

Electromagnetic vibration feeding

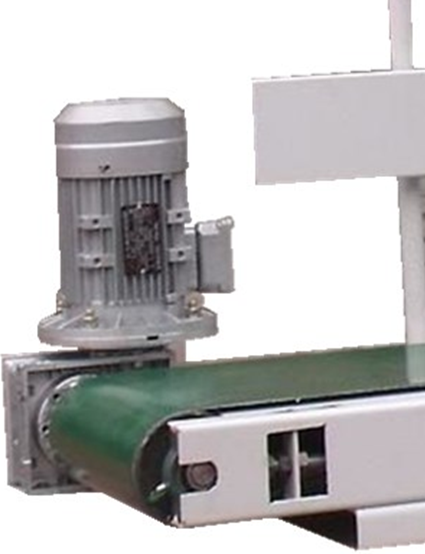

Conveyor belt, it is used for transferring bags.

Normal type

By adjusting the height of sewing machine and belt conveyor, it can use different size bags.

Gear motor is belong one part of conveyor belt. It is made from China top brand electricity motor manufacturer, which has high quality and aluminous cover.

Air Compressor

Automatic thread trimming, with counter

Foot Switch