5BY-13P Batch Type Seed Coating Machine

Brief introduction

Seeds and seed coating agent are uniformly mixed according to the prescribed ratio and form a coating film on seeds` surface. It improves seeds` disease prevention and insecticidal effect after sowing. Batch type seed coating machine is an important model in the seed processing and production.

Application scope

The coating machine capacity is 10 ~12 tons per hour, which is widely used in the coating and processing of wheat, barley, rice, corn, sorghum, beans and various crop seeds.

Working Principle

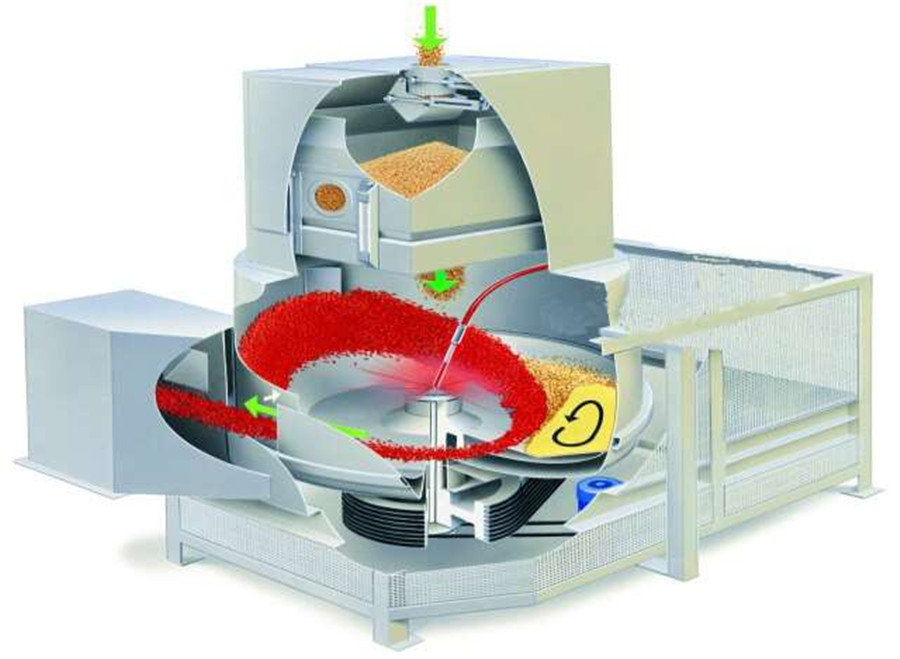

The core of seed coating machine is mixing bowl, which rotates at bottom. Each batch of seeds are gradually dropped into mixing bowl after scale weighing.

The rotation of mixing bowl raises seeds to wall, so that seeds are evenly spread. This coating machine can be used to coat both liquidity coating agent and powder coating agent. Coating liquid is fed from the peristaltic pump. The powder liquid is fed from the screw auger.

The spinning plate in center of mixing bowl transfers the liquidity coating agent from the dispensing system. The liquid medicine is atomized at the high speed rotation. And attach into the seeds` surface. This liquid is highly uniform.

All types of coating agents, whether liquid or powder, are fully and effectively utilized in this system.

Structural Features

1. The seed feeding method is weighing type, each batch can be adjusted arbitrarily between 10-120KG.

2. The coating liquid supply is fully digitally adjusted peristaltic pump and load cell dual control modes. So liquid medicine is accurately and evenly transferred to mixing tank, ensures coating agent and seeds ratio can be accurately adjusted within 1: 260.

3. The atomizing system drives the spinning plate rotates at a high speed by motor, so that coating liquid that reaches mixing chamber is evenly atomized and then sprayed onto the seeds` surface to further ensure the uniformity mixing of the coating liquid and seeds.

4. Powder feeding device, which can coat and pill the seeds with coating powder.

5. The machine has touch screen and PLC control system to make operation control fully automatic.

6. In addition, the machine can be equipped with a heating device to improve the coating quality and drying speed of seeds in low temperature environment.

Data

| item | unit | parameter |

| Designed capacity | Ton per hour | 12 |

| Capacity per batch | KG | 10-80 |

| Coating time | Seconds per batch | 20 |

| Main machine power | KW | 20 |