5XZC-5DH Seed Cleaner & Grader

| item | value |

| Warranty | 3 Year |

| Online support | |

| Applicable Industries | Farms |

| After Warranty Service | Online support |

| Local Service Location | Poland |

| Showroom Location | Poland |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | Ordinary Product |

| Warranty of core components | 3 Year |

| Core Components | Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear |

| Type | New |

| Use | Individual farmers, seed processing companies, seed exporters and grain warehouses |

| Place of Origin | Poland |

| Brand Name | Optigran |

| Condition | New |

| Key Selling Points | High Productivity |

| Material | Carbon steel |

| Weight | 1600kg |

Introduction

Air-screener has 3-4 layers sieve, With a very wide range of sieves available, this machine is very versatile and can be used for seed cleaning of almost all crops.

The machines sift based on aerodynamics and the surface speed difference of seed and impurities, adjusting the seed of the air current. As impurities are light, they are sucked into the cyclone duster, while seed is heavy and is transferred into a vibrating screen. The vibrating screen has Three layers sieves with four outlet which eject large impurities, small impurities and seed respectively, The vibration screen used for separating seeds according different sizes.

Features

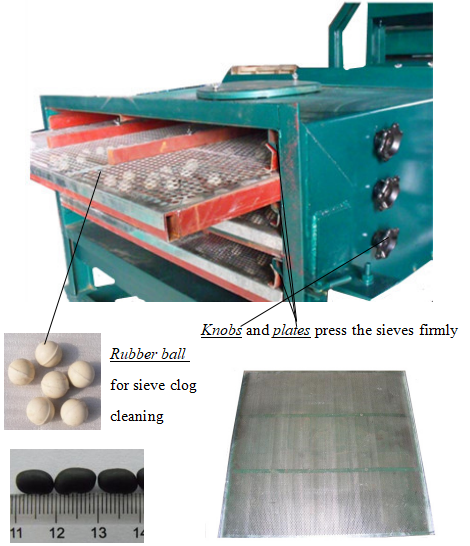

1.The machine works with 3 or 4 sieve levels, The sieve are cleaned on ball frames, with rubber balls.

2.The rubber ball sifting structure complies with international standards, Sanli’s patented rubber ball is highly elastic, endures and long lasting.

3. The sieves are tightly fit in the machine by a clamp-locking system for quick changing of the sieves and thorough cleaning of the machine.

4.The volume of air is variable and adjusted from minimum to maximum by a controlling handle, assuring very accurate cleaning and sorting of seeds. The blower has a very stable and reproducible output.

5. Transparent inspection windows for easy inspection and clean out.

6. The machine has a very low noise level.

7. Very easy and thorough cleaning of the machine and no contamination risk.

8. No wooden frames on the sieves where seeds can hide.

9. With cyclone duster, Environmentally friendly model.

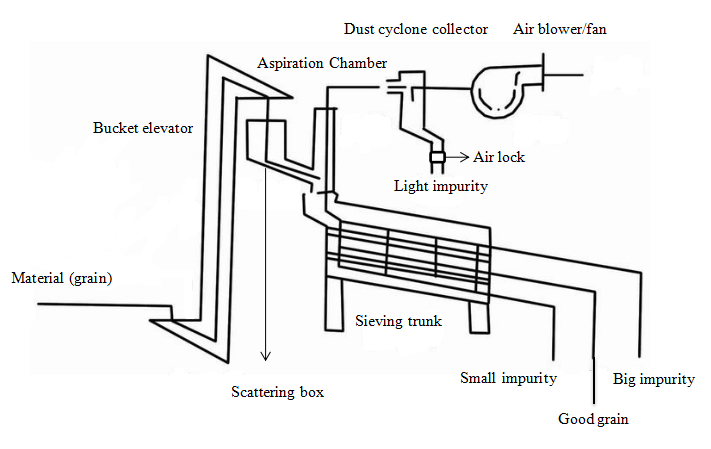

Working principle sketch

Working principle

Feed grain into inlet hopper after air sieving, and then under the vibration the grain jumping and flow to the multi-layer sieving trunk, following the grains well-proportioned enter to the upper layer sieve via the rubber curtain. Selected grains will fall into the next lower sieving panel after sieving, chaff and debris blocked by sieves and transfer to the outlet of large impurity. The selected grains will fall into the lower layers sieving panels, and will be graded into different levels of the different grain sizes by sieving in different sieving layers, that caused by the layers sieving panels have different mash size. Selected grains flow to the outlets of good grain, fill into bag hung on the bag holder. Cap of outlets can be used when shift bagging that means the cap can be close when you change the bag. It is the whole work flow for the separator.

Use different sieve to different process of different type of grains. The observing windows on the sieving trunk are for checking operation.

Multi-angle display

Aspiration Chamber(Wind Sieve)

Removing dust, straws, hey, husk and other light weight impurity out of the grain.

Handle and knobs adjusting the gap of channel (wide at top and narrow at bottom) to obtain optimum aspiration separating result. Removal of all the light weight impurity while fine seed falling down.

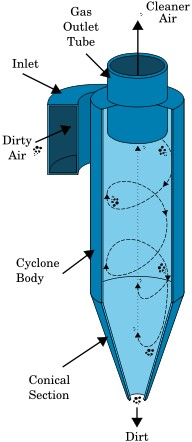

Dust removal system

Cyclone dust separator is a professional method of removing particulates from an air, gas or liquid stream, without the use of filters.

Rotational effects and gravity are used to separate mixtures of solids and fluids.

Air flow adjusting handle

Air lock discharge the impurity from dust cyclone separator and keep air pressure of aspiration system

Handle for adjusting grain flow scattering evenly

Grain lifted up by bucket elevator and fall into grain scattering box, where grain flow scatter evenly, in case of the grain gather at one side. After that grain fall into sieving trunk and light impurity was removed by aspiration simultaneously.

Handle for adjusting grain flow scattering evenly

Scattered grain feed into sieving trunk for separating. In this part, grain / seed was graded by galvanize sheet with different holes in each layer. Big size and small size impurity discarded in different outlets respectively. Final cleaned seed come out from main outlet.

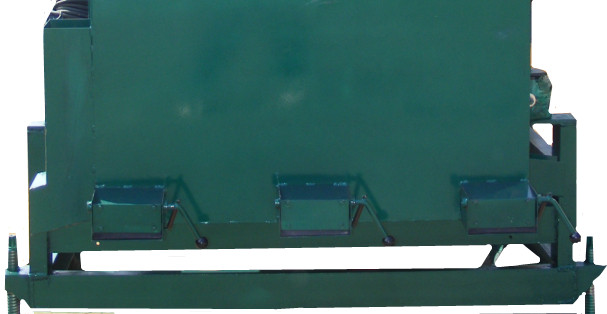

Good seed outlets

It’s very convenient to pull the sieves out. Client can change the sieve easily when cleaning other grain or seed.

The sieves inside are made of durable galvanized steel sheet. We will equip suitable sieves hole according to client’s raw material.

In order to choose perfect sieves, the seed sample (raw material contains impurities) or seed measuring photo are needed after clients placed order. Note that one set sieves are equipped as standard supply, only used for one species seed.

Note: Stainless steel sieve is available.

Bucket elevator

Used to transfer materials (grains). Available in both fixed and movable version to adapt different working environment.

Feature

It has compact structure, user friendly interface, easy to maintain, energy saving, easy to clean, efficiently avoid mixture.

Power control cabinet

It has the feature of easily operating, only need to

connect the power. The wire is 100% copper,

which lead to long using life.

|

Dimension (L×W×H) |

4970×1900×3100 mm |

|

Dimension of each sieve layer |

2000×1000 mm |

|

Capacity (count by wheat) |

5000 kg/h |

|

Weight |

1600 kg |

|

Motor Power Air Blower Vibration Motors Elevator Motor Air Lock |

5.5 kw 0.37 kw*2 0.75 kw 0.75 kw |

|

Total Power |

7.74 kw |