High Quality Air Screen Cleaner - 5XZC-L Laboratory Seed Cleaner & Grader – SYNMEC

High Quality Air Screen Cleaner - 5XZC-L Laboratory Seed Cleaner & Grader – SYNMEC Detail:

Parameter reference:

| Name | Laboratory seed cleaner and grader |

| Model | 5XZC-L |

| Capacity | 100 kg/h |

| Air blower power | 0.75 kw |

| Vibration power | 0.37 kw |

| Voltage | 220V/50Hz |

| Vibration frequency | 0-400 times/min |

| Amplitude | 15 mm |

| Dimension | 1500×1170×2220 mm |

| Air blower specification | DF-6, ,1210mmHG |

| Air blower motor specification | 2800r/min,220V,50Hz |

| Vibration motor specification | YS-7124,1400 r/min |

Function:

The 5XZC-L seed cleaner & grader is a precision cleaner for particulate material cleaning and grading. It suitable for separation of all seed types as grain seeds, grass seeds, flower seeds, vegetable seeds, herb seeds and so on.

Working principle:

It is the air screen structure with front and rear air cleaning systems. In air cleaning procedure, it removes dust, light impurities and unfilled grains. Sieve trunk is equipped in three sieve layers which used to separate a large impurity, large seeds, and small impurity small seed. After processing, qualified seeds are separated.

Feature:

Seed cleaning machine is mainly used for all kinds of seed processing characteristics test. It is widely also used for quantity high-value seeds cleaning and size classification. The machine is air screen structure. It with former and rear duct separating air pipes, so you can clean the dust, light impurities and blighted grains from good seeds. Vibrating sieve trunk is installed 3 sieve layers in the upper, middle and lower part. First sieve layer is used to separate large impurity & large seeds. Second sieve layer is used to separate small impurity & small seed. The rest seeds are qualified seeds and they go to the main discharge outlet. By adjusting the frequency button on vibration sieve trunk, you can control the material running speed on sieve screen surface. So you can well manage the seed cleaning quality by adjust trunk vibration frequency. Dusty air produced after winnowing will be discharged after filtering. This is environmental protection design.

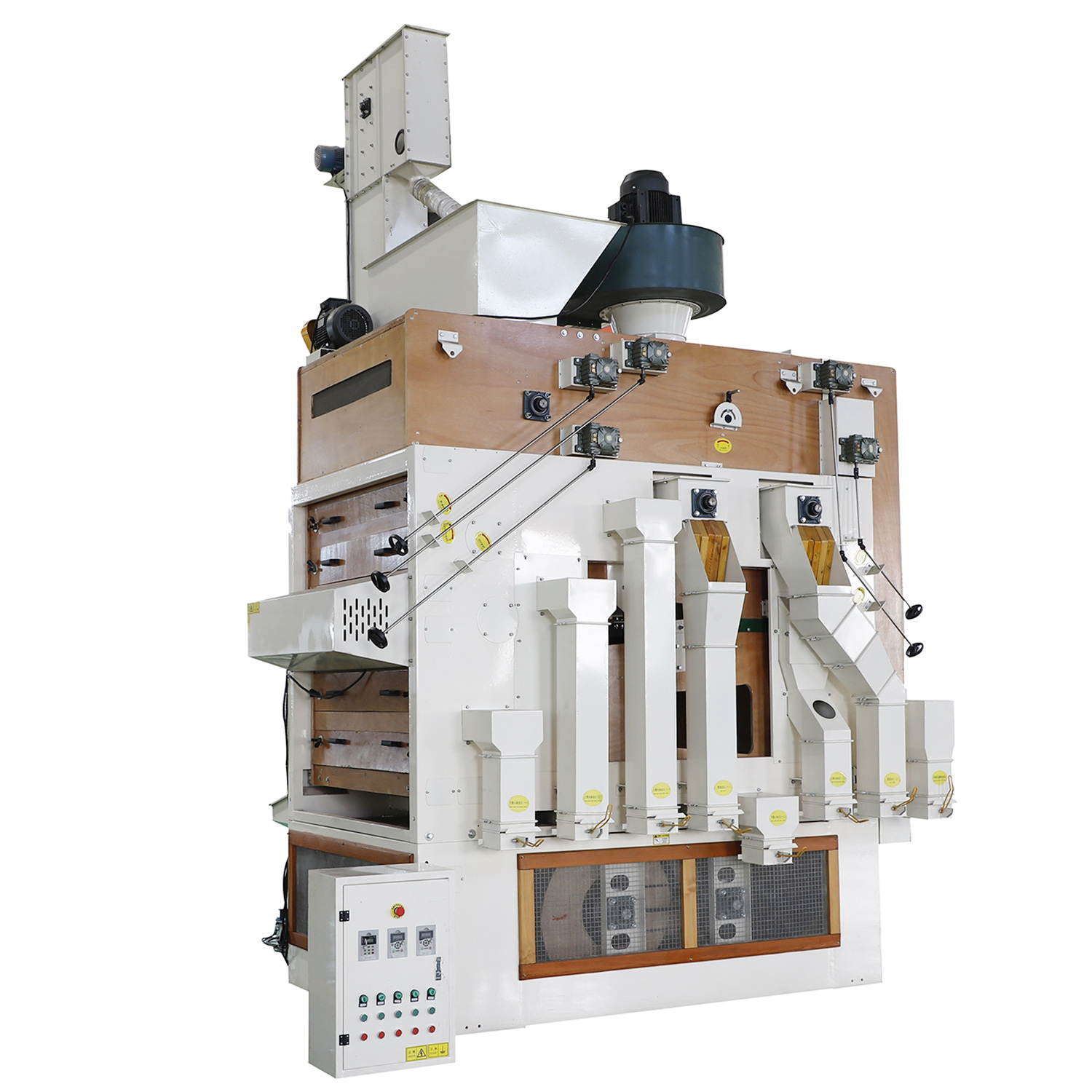

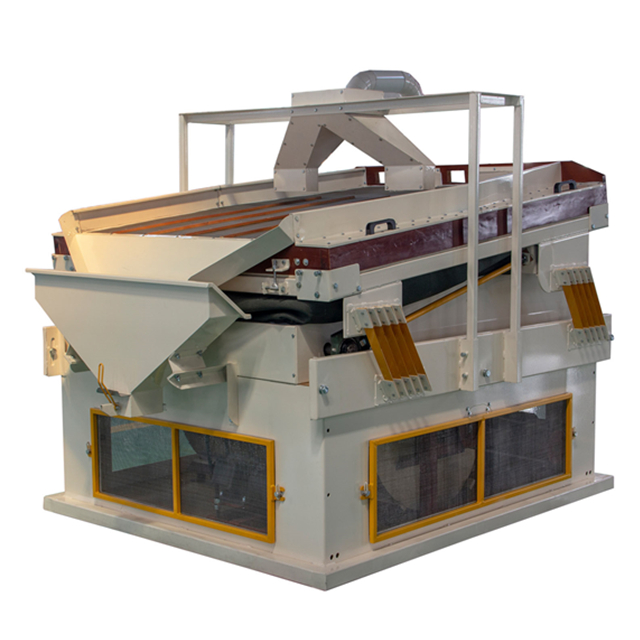

Laboratory seed cleaner and grader construction:

Product detail pictures:

Related Product Guide:

Always customer-oriented, and it's our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for High Quality Air Screen Cleaner - 5XZC-L Laboratory Seed Cleaner & Grader – SYNMEC , The product will supply to all over the world, such as: India, Munich, Dubai, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.